How to digitize P&IDs from paper to digital format to save time and money? How to transfer tons of paper documents to a hard drive or even to the cloud? Thanks to P&ID digitization software and AI-powered P&ID digitization, converting scanned documents into readable and editable digital files is quite simple. This is a perfect solution for automated data extraction from P&ID diagrams in the process industry.

What is OCR?

In the age of rapid technological progress, digitalization covers more and more spheres of human life from finance to space travel. So it is logical to use all the advantages of document digitization and digitizing piping and instrumentation diagrams.

The technology consists of hardware and software processing methods used to convert paper documents into machine-readable text. Modern OCR software integrates machine learning and artificial intelligence (digitalization AI), AI for data analytics, and predictive analytics to implement accurate recognition methods, such as language identification or handwriting styles.

How OCR Transforms Engineering Data in Process Industry

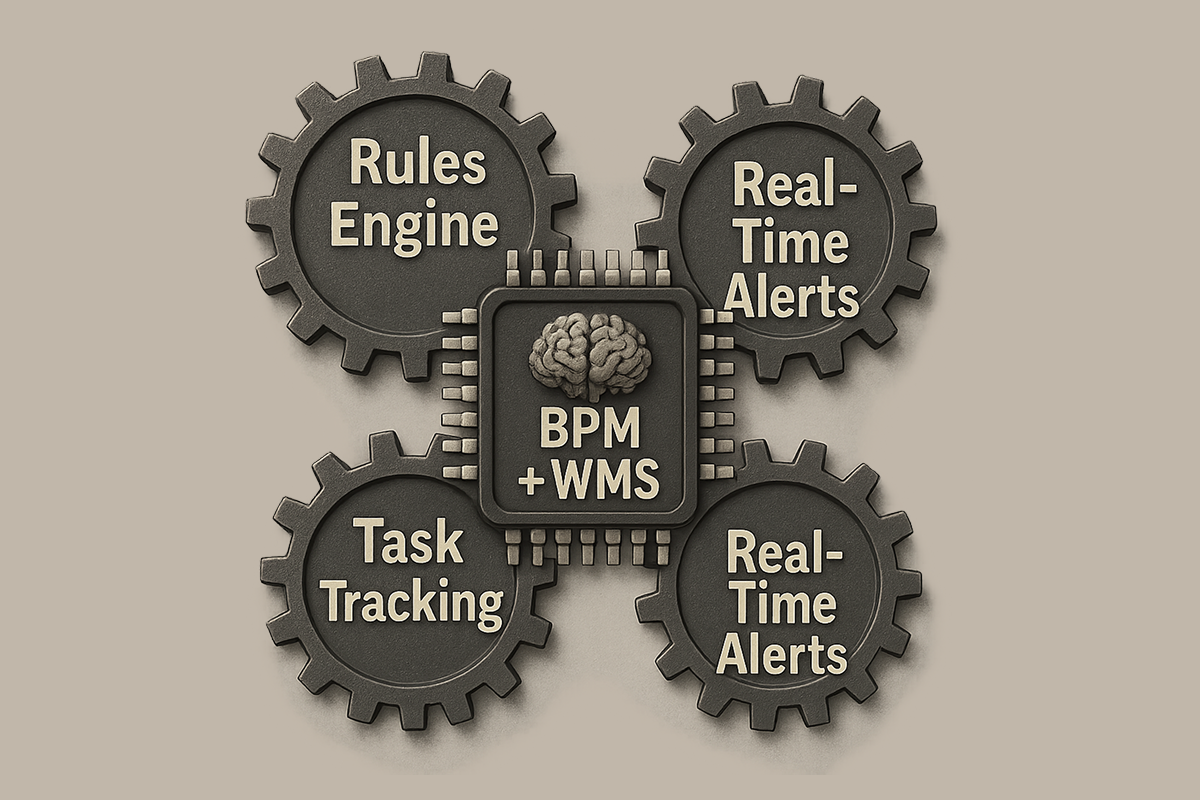

Digitization transforms how engineering teams handle P&ID data. Traditional time-consuming manual methods are being replaced by AI-powered P&ID software that enables intelligent P&IDs and digital twin integration with P&IDs. This allows process industry professionals to access engineering data instantly while maintaining accuracy.

AI-powered data extraction enables:

- Real-time access to process flow documentation;

- Intelligent digital workflows for engineering teams;

- Data-driven decision making with accurate P&ID data;

- Integration with digital twin technology for predictive maintenance.

Why Businesses Need P&ID Software for Document Digitization

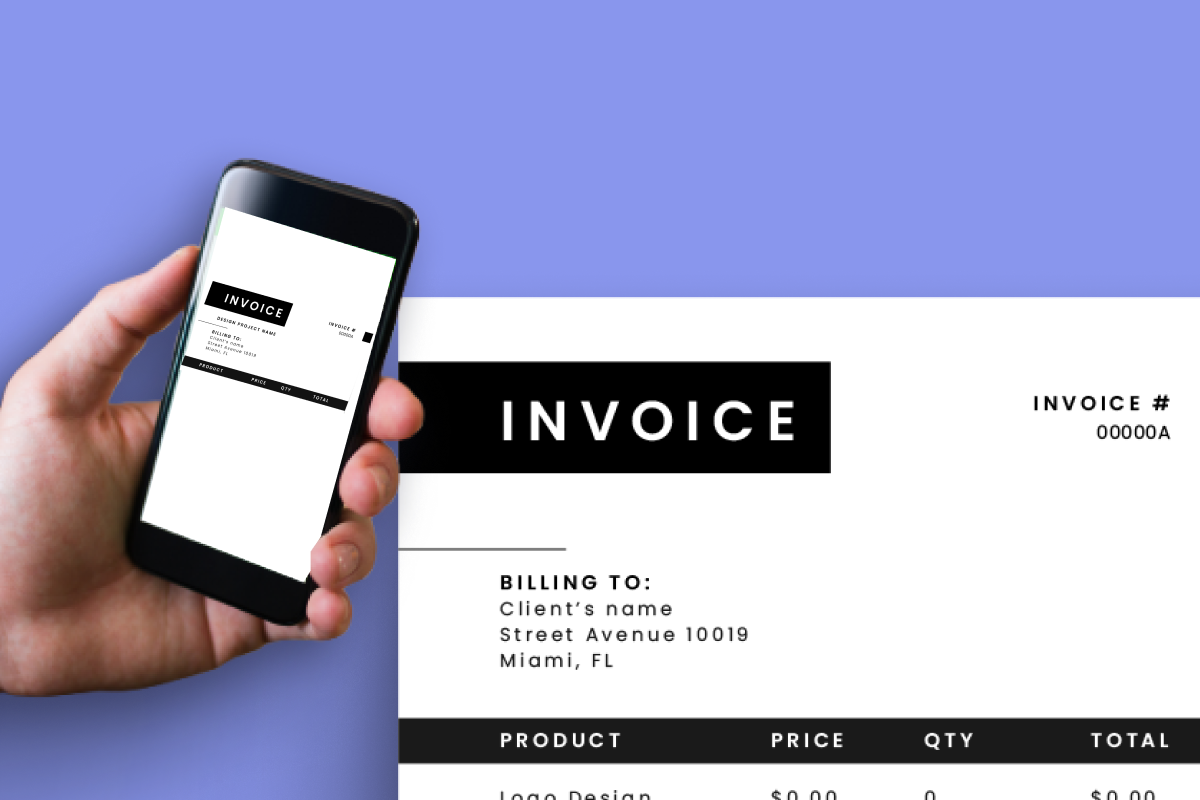

Imagine that you have a paper document, for example, a P&ID diagram you need to digitize. Manual retyping is time-consuming, while AI-powered OCR allows automated data extraction and ai p&id extraction for fast and accurate conversion to digital formats like docx, txt, XML, or CSV.

Scanning and text recognition are crucial stages in document digitization processes. Automated data extraction requires less time to convert the paper document into a digital format (like .rtf, .doc, .docx, .txt) than manual text retyping or even P&ID drawings redrawing. As a result, you get a document that you can process by any text editor.

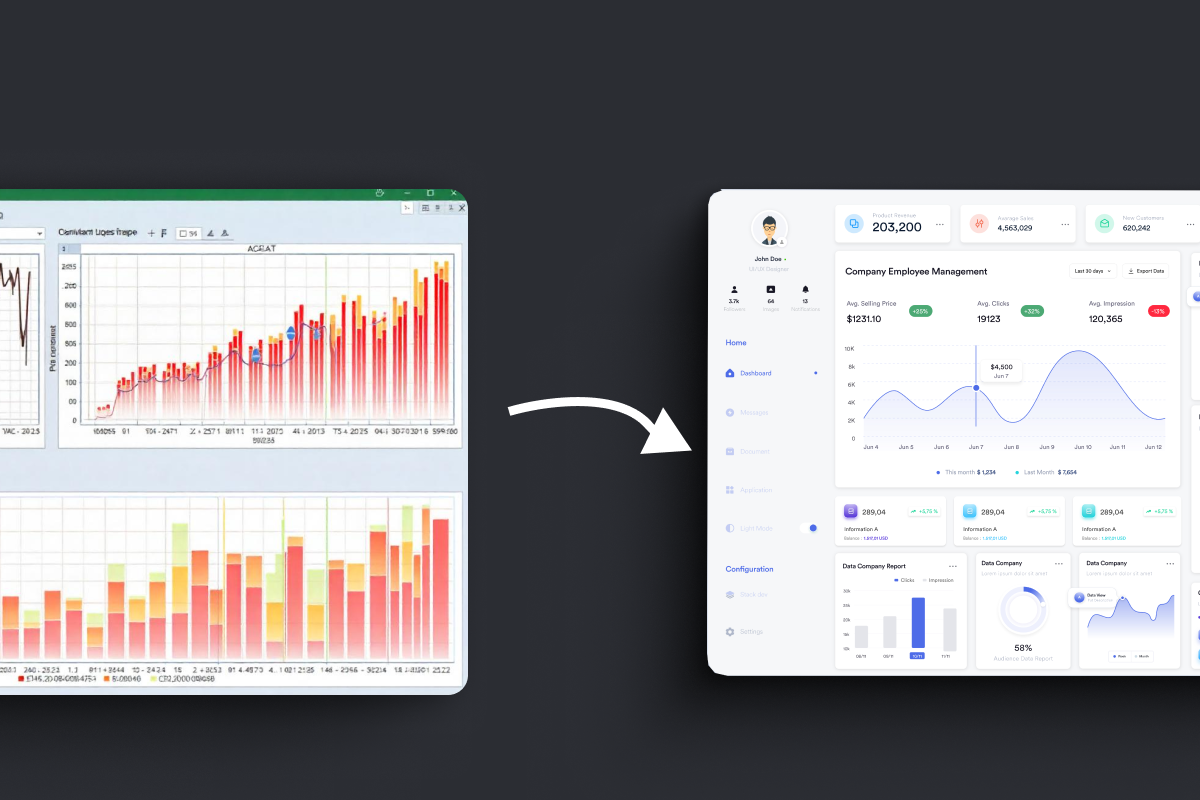

| Feature | Manual Method | AI-Powered P&ID Software |

|---|---|---|

| Processing Speed | 1 document/hour | 5,000+ documents/hour |

| Accuracy Rate | 85-90% | 97%+ |

| Cost per Document | 5x higher | Baseline |

| Engineering Data Access | Time-consuming search | Instant digital retrieval |

| Digital Twin Integration | Not possible | Fully supported |

Document digitization helps to:

- Digitize P&IDs including complex charts and P&ID diagrams;

- Provide AI-powered data extraction and data analysis capabilities.

- Store important engineering data in a digital database with editing capability;

- Train machine learning models for higher recognition accuracy over time;

- Enable digital twin technology for real-time monitoring;

- Support data-driven workflows in the process industry;

- Integrate with command line tools for automated processing;

- Create intelligent P&IDs with searchable metadata.

It's All About Azati OCR: AI-Driven P&ID Software

Azati OCR is an AI-powered software development solution for digitizing piping and instrumentation diagrams, based on artificial intelligence, machine learning, and advanced data extraction capabilities.

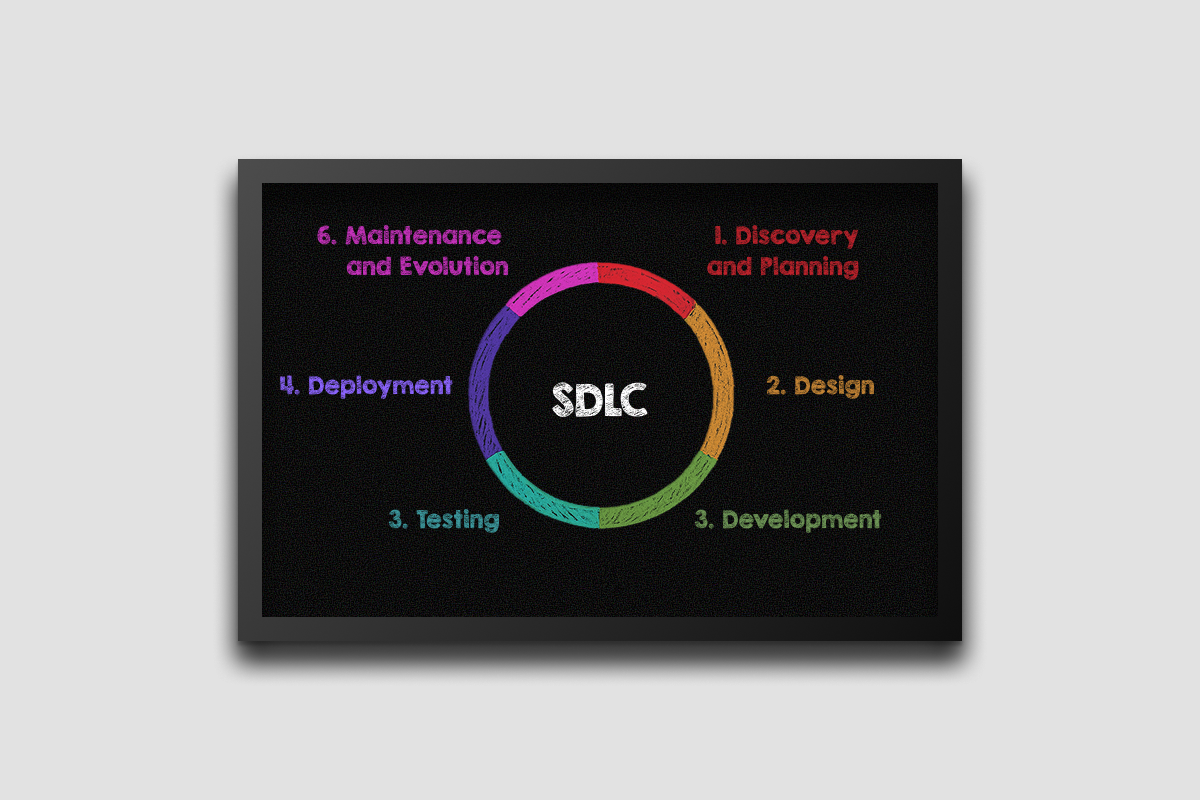

Let us briefly explain how Azati OCR works.

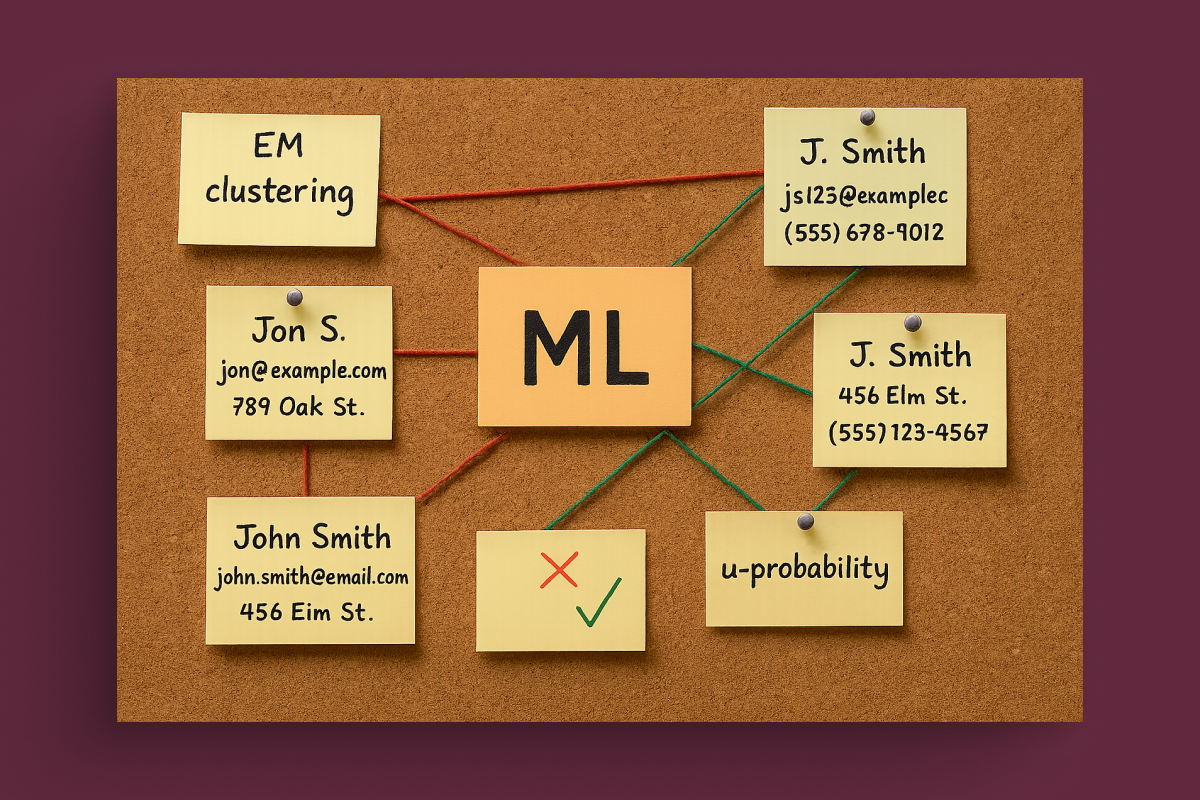

Step #1: Machine Learning Training for Intelligent P&IDs. Our engineers use documents to train the machine learning models. It is a necessary step to create a possibility to recognize documents fields and automatically divide them into different categories, such as invoices, passports or P&ID diagrams. Afterward, the system can define a template for the documents with similar fields and sections.

Step #2: Template Mapping for P&ID Data Extraction. When templates are already predefined it becomes easy to process volumes of one-type or similar documents automatically. To achieve maximum accuracy, Azati specialists manually map documents fields.

Due to the integration of artificial intelligence and computer vision, Azati OCR provides automatic layout detection and ai p&id extraction. It aimed to look for similarities in different documents and processes these parts separately. After all OCR connects all the pieces found in the single document into a template.

This method we usually apply to complex documents containing charts, P&ID diagrams, images or other non-text characters. At first, the abbreviations and designations are defined manually, and then these objects are searched in all documents.

Step #3: Automated Processing and Data Extraction. Azati OCR processes each document several times to increase accuracy and processing efficiency. As a result, the system exports all the extracted engineering data (in the structured or semi-structured form) to any possible format, for example: XML, CSV, JSON, or plain text. The P&ID software also supports command line integration for seamless workflow automation.

Our engineers can deploy the OCR engine in every country, or even to a self-made cloud without any access from the Internet. At Azati, we respect user privacy and data security.

Azati OCR Benefits: Why Choose Our AI-Powered Solution

Today, there is a considerable amount of digitization software on the market of similar tools. However, most of them are insufficient for most corporate needs in the process industry, especially when it comes to data extraction from P&ID diagrams. These documents have a complex structure due to the presence of a large number of non-text characters.

Let's have a look at the main benefits of the Azati OCR

#1 AI-Driven Product for Intelligent Digital Workflows

To efficiently analyze, recognize, and digitize P&IDs that contain diagrams, charts, or images, Azati improved the product by integrating artificial intelligence, machine learning and computer vision. It helps increase recognition accuracy: each new document added to the database is used to train and improve the mapping algorithms, creating truly intelligent P&IDs.

#2 High Accuracy of Character Recognition and Efficiency

At the moment, Azati OCR allows:

- Decrease single document processing cost by 5 times (compared to manual digitization);

- Reduce document processing time (120K documents in less than 24 hours);

- Speed up data extraction process 4x faster;

- Increase character recognition accuracy to 97%.

#3 Flexible Payment Options for P&ID Software

Most of the similar products on the mass market provide only one payment method – subscription. This is convenient for companies who want to systematically and continuously process and digitize P&IDs. However, this approach is not always suitable for those who want to handle a massive group of documents once.

Therefore, Azati OCR provides the ability to pay in two ways:

- Pay-per-Document: you pay for each processed document, depending on the document’s complexity – ideal for many different documents. Our engineers continuously improve the system, and recognition quality increases over time.

- An independent version: we install our engine in your environment at a fixed price and sign a maintenance contract. This option is best for small amounts of well-standardized documents, regardless of complexity.

How Azati OCR Treats Piping and Instrument Diagrams

P&ID diagrams contain complex components such as valves, pumps, and vessels. With AI-powered digitization of P&IDs, predefined templates and ai p&id extraction enable automated processing. Machine learning and data science techniques continuously improve processing accuracy of P&ID data.

All this requires in-depth knowledge from specialists, strict adherence to the rules, and specialized technological requirements for the construction and installation of pipelines in the process industry.

Due to a large number of relevant documents that engineers should use while designing, construction, and further maintenance, digitization transforms time-consuming manual processes, speeds up data extraction, and converts paper versions to digital format for easier editing of P&ID drawings.

Common P&ID Components We Extract:

Often P&ID consists of the following components:

- Symbols of pipe fittings (valves, taps, gate valves, etc.);

- Vessels;

- Pumps, Fans & Compressors;

- Numbers & letters inside the characters;

- Designation of control signals;

- Process flow indicators;

- Engineering data annotations;

- Other elements.

Predefined templates allow recognizing sections, image segments, and abbreviations to ensure high automation of digitizing piping and instrumentation diagrams.

When Manual Intervention is Needed

Sometimes Azati OCR cannot match a document to a predefined template.

There are two scenarios of document processing:

- Manual mapping to extract data from custom diagrams with high complexity requiring human help.

- Partially automated data extraction when Azati OCR handles all possible symbols and designations that can be recognized. Later it expects the user to determine which information is useful and which is not.

How to Use Azati OCR for Automated Data Extraction from P&IDs

P&IDs (piping and instrumentation diagrams) are diagrams showing the relationship of technological equipment and devices used to control the process flow.

P&ID diagrams play an important role in maintaining and modifying the process that they describe. It is very important to demonstrate the physical consistency of the equipment. Digitization transforms how process industry teams access and utilize this critical engineering data.

There are several stages where Azati AI-powered P&ID software is helpful:

Re-design the Layout of the Technological Process (System)

Pipeline design is a crucial part of the construction process in many domains, such as industrial or petroleum engineering.

At the same time, solving key problems like pipeline layout, selecting the necessary fittings, and developing specifications can be challenging. These tasks can be successfully simplified by converting time-consuming paper documents into digital formats using Azati OCR.

Hardware Specification Processing

The specification of equipment and materials is a text project document that contains information on each element's composition and basic characteristics.

Document digitization provides the possibility to make all necessary changes and edits faster and efficiently by using specific P&ID software without manual text retyping. This enables data-driven decision making.

Analysis of Operational Hazards

It is critical to solve issues related to the prevention of potential emergencies to minimize technological risks. This is especially relevant to ensure the safety of petroleum facilities in the process industry, the operation of which is carried out with an increased risk of transportation or storage accidents.

Digital charts and intelligent P&IDs can help to check system status more accurately and provide the ability to apply various ways to solve existing problems without redrawing or retyping.

Maintenance and System (Process) Modifications with Digital Twin Integration

For further maintenance and modification of pipeline systems, engineers need all previous documentation and P&ID drawings that are much more economical and efficient to store on digital media.

Moreover, thanks to digitization of piping and instrument diagrams, it becomes possible to make edits without rewriting or redrawing them from scratch. AI-driven data extraction enables digital twin technology integration for predictive maintenance and real-time monitoring.

ROI: Why Digitize P&IDs Now?

Average Company Savings:

- Labor costs: 80% reduction in time-consuming manual data entry.

- Error correction: 90% fewer mistakes in engineering data.

- Storage costs: 95% reduction vs. physical archives.

- Process efficiency: 4x faster access to P&ID data.

- Digital twin readiness: Enable intelligent digital infrastructure.

Conclusion

Before AI-powered P&ID software like Azati OCR, the only method of paper digitization was manual text reprinting. This process was time-consuming, and also often led to a lot of mistakes. Azati OCR saves time, helps to eliminate errors and minimize effort.

The technology allows you to perform actions that are not available for physical copies. For example, you can perform compression to ZIP files, highlight keywords, post documents on a website, attach them to e-mail, and integrate with digital twin platforms for intelligent P&IDs.

Digitization transforms how the process industry manages engineering data. Our AI-driven solution enables data-driven decision making, supports intelligent digital workflows, and provides the foundation for advanced capabilities like digital twin technology.

How our team makes a personalized demo:

- You send us a few samples for OCR training.

- You send us another group of documents, and we show you how the system processes these documents in real-time.

- We tune an engine to decrease the number of errors and run processing for a huge set of documents

- Our specialists send you the results, reports, and comments concerning your samples.

If you need a product to digitize your complex documents containing Piping and Instrumentation Diagrams – drop us a line and we’ll have a chat on how Azati OCR can help your business.